PERMASCOPE MP0: Probe integrated in the measuring instrument for single-handed operation

PERMASCOPE MP0-FP: Probe with cable (80 cm; 31.5 “) permanently connected to the instrument, for measurements on various specimen shapes

Coating thickness pocket gauge – MP0 is a specially designed measuring instrument to measure coating thickness rapidly and accurately. This coating thickness pocket gauge - MP0 is perfect for instant anywhere use due to its small size, light weight and reliable design. These are crafted to perform operations like menu navigation and have graphic display. Coating thickness pocket gauge unveils the reading of measurement in seconds and displays it directly on the top. This coating thickness pocket gauge - MP0 is customized with different language options thus fulfilling the requirement of different language users.

PERMASCOPE MP0: Probe integrated in the measuring instrument for single-handed operation

PERMASCOPE MP0-FP: Probe with cable (80 cm; 31.5 “) permanently connected to the instrument, for measurements on various specimen shapes

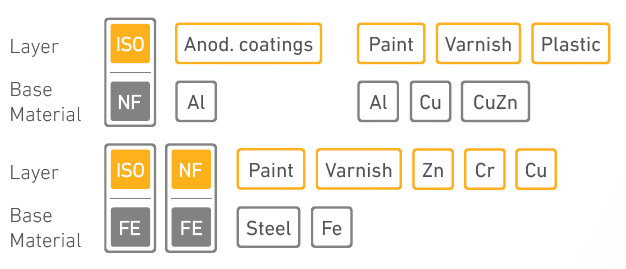

Zinc, chromium, copper, paint, varnish and plastic coatings on steel, iron or cast iron (Fe)

Measurements both on smooth and rough surfaces

Statistics:Display of mean value, standard deviation, MIN, MAX and number of all

measurements stored in the instrument memory

Units of measurement:Selectable μm or mils

Continuous display mode:Measurement in "continuous display mode" for continuous sampling

of thesurfaces, e.g., in the manufacture of tanks and containers.

Normalization:Adaptation to the substrate material and the shape of the specimen.

Calibration:Factory calibration

With the greatest Each individual instrument is factory calibrated at several

reference points care to ensure the highest possible degree of trueness.

Calibration (Adjustment)

Adaptation to the substrate material and the shape of the specimen

and to a thickness value using a calibration foil.

Simple Calibration

Adaption to the coating and substrate material in one step using a

coated reference part with a coating thickness higher than 200 μm

(7.87 inches). This kind of calibration supplies only a lower accuracy.

Measuring method:Magnetic induction method (ISO 2178, ASTM D7091, Measurement of

non-magnetic coatings on magnetic substrates)

Probe:Probe tip radius: 2 mm (78 mils); Probe tip material: Hard metal

Data memory:Max. 1,000 individual readings; the contents of the memory is retained

even without batteries

Measuring frequency:Automatic upon placement of the probe; indication of the measurement

with a beep visually with a green lit LED

Display:Graphic display, in addition to the measurement reading the mean value

and the standard deviation or the number of measurement reading can also

be displayed.LCD display on the top side of the instrument, e.g., for reading

the measurement value for measurement overhead

Admissible ambient:0 .... +40 °C (+32 ... +104 °F)

temperature range during

operation:

Weight (incl. batteries):MP0: 137 g (4.8 oz)

MP0-FP: 184 g (6.5 oz)

Power supply:2 Batteries, LR6, AA, 1.5 V

Coating thickness pocket gauge – MPoR is a pocket device with integrated USB for appropriate and quick coating thickness measurement on all metals effectively. Its structure and permeability have less effect on measurement result when compared with other devices. Coating thickness pocket gauge - MP0R has two remarkable measuring methodology in agreement with measurement regulation IMO PSPC (90/10-Rule) and SSPC.PA2. Coating thickness pocket gauge – MPoR is easy to carry as it is insubstantial and has resilient design which is highly appreciated in the market.

PERMASCOPE MP0R: Probe integrated in the measuring instrument for single-handed operation

PERMASCOPE MP0R-FP: Probe with cable (80 cm; 31.5 “) permanently connected to the instrument, for measurements on various specimen shapes

Paint, varnish or plastic coatings on aluminium, copper or brass

Anodized coatings on aluminium

Statistics:Display of mean value, standard deviation, MIN, MAX and number of

measurements per block

PC softwarePC software FISCHER DataCenter with the following functionality:

included in theTransferring and archiving measurement data,comprehensive

scope of supply:statistical and graphical evaluations, easy creation and printing

of inspection reports.

Block size:Adjustable between 2 and 20 single readings per block

Tolerance limits:Adjustable, depending on the selected measuring mode

Offset value:In the standard mode, the freely adjustable offset value is deducted

automatically from the measured value. Thus, one obtains the thickness

of the top coating if for instance the interim coating is known.

Calibration:Factory calibration

Each individual instrument is factory calibrated at several reference points

with the greatest care to ensure the highest possible degree of trueness.

Corrective calibration (Adjustment)

Adaptation to the substrate material and the shape of the specimen and

to a thickness value using a calibration foil.

Simple Calibration

Adaption to the coating and substrate material in one step using a coated

reference part with a coating thickness higher than 200 μm (7.87 inches).

Nevertheless, this kind of calibration supplies only a lower accuracy as

specified in the sections Trueness and Repeatability Precision.

Measuring method:Magnetic induction method (ISO 2178, ASTM D7091, Measurement of

non-magnetic coatings on magnetic substrates)

Probe:Probe tip radius: 2 mm (78 mils); Probe tip material: Hard metal

Data memory:Max. 1,000 individual readings; the contents of the memory is retained

even without batteries

Measuring frequency:More than 70 measurements per minute

Display:Graphic display, in addition to the measurement reading the mean value

and the standard deviation or the number of measurement reading can also

be displayed.LCD display on the top side of the instrument, e.g., for reading

the measurement value for measurement overhead

Display limit value violation:Acoustically through 2 short beeps and visually with a red

lit LED

Languages:Many different display languages are selectable: German, English and

several other European and Asian languages

USB port:2.0 compatible, mini type B socket, for connecting a PC

Data transfer:Single readings, mean values, group separator

Admissible ambient 0 … +40 °C (+32 … +104 °F)

temperature range during

operation:

Weight (incl. batteries):MP0R: 137 g (4.8 oz)

MP0R-FP: 184 g (6.5 oz)

Power supply:2 Batteries, LR6, AA, 1.5 V

Coating thickness pocket gauge – MPoR-FP is a pocket instrument consolidated with PC for suitable and rapid coating thickness measurement on all metals adequately. Coating thickness pocket gauge - MP0R-FP has proprietary conductivity compensation for calculation on non-magnetic substrate materials. Coating thickness pocket gauge - MP0R-FP is portable due to its hard-wearing structure and it also ensures that it never fails while working under unfavorable conditions. MPoR –FP is available for all our customers at standard price.

DUALSCOPE MP0R: Probe integrated in the measuring instrument for single-handed operation

DUALSCOPE MP0R-FP: Probe with cable (80 cm; 31.5 “) permanently connected to the instrument, for measurements on various specimen shapes

Zinc, chromium, copper, paint, varnish and plastic coatings on steel, iron or cast iron (Fe)

Paint, varnish or plastic coatings on aluminium,copper or brass

Anodized coatings on aluminium

Statistics:Display of mean value, standard deviation, MIN, MAX and number of

measurements per block

PC softwarePC software FISCHER DataCenter with the following functionality:

included in Transferring and archiving measurement data,comprehensive

the scope of supply:statistical and graphical evaluations, easy creation and printing

of inspection reports.

Block size:Adjustable between 2 and 20 single readings per block

Tolerance limits:Adjustable, depending on the selected measuring mode

Offset value:In the standard mode, the freely adjustable offset value is deducted

automatically from the measured value. Thus, one obtains the thickness

of the top coating if for instance the interim coating is known.

Units of measurement:Selectable μm or mils

Continuous display mode:Measurement in "continuous display mode" for continuous sampling

of the surfaces,e.g., in the manufacture of tanks and containers.

Normalization:Adaptation to the substrate material and the shape of the specimen.

Calibration:Factory calibration

Each individual instrument is factory calibrated at several reference points

with the greatest care to ensure the highest possible degree of trueness.

Corrective calibration (Adjustment)

Adaptation to the substrate material and the shape of the specimen and

to a thickness value using a calibration foil.

Simple Calibration

Adaption to the coating and substrate material in one step using a coated

reference part with a coating thickness higher than 200 μm (7.87 inches).

Nevertheless, this kind of calibration supplies only a lower accuracy as

specified in the sections Trueness and Repeatability Precision.

Measuring method:Magnetic induction method (ISO 2178, ASTM D7091, Measurement of

non-magnetic coatings on magnetic substrates)

Probe:Probe tip radius: 2 mm (78 mils); Probe tip material: Hard metal

Data memory:Max. 10,000 individual readings; the contents of the memory is retained

even without batteries

Measuring frequency:More than 70 measurements per minute

Measurement acquisition:Automatic upon placement of the probe; indication of the

measurement with a beep visually with a green lit LED

Display:Graphic display, in addition to the measurement reading the mean value

and the standard deviation or the number of measurement reading can also

be displayed.LCD display on the top side of the instrument, e.g., for reading

the measurement value for measurement overhead

Display limit value violation:Acoustically through 2 short beeps and visually with a red

lit LED

Languages:Many different display languages are selectable: German, English and

several other European and Asian languages

USB port:2.0 compatible, mini type B socket, for connecting a PC

Data transfer:Single readings, mean values, group separator

Admissible ambient 0 .... +40 °C (+32 ... +104 °F)

temperature range during

operation:

Weight (incl. batteries):MP0R: 137 g (4.8 oz) ; MP0R-FP: 184 g (6.5 oz)

Power supply:2 Batteries, LR6, AA, 1.5 V

Measuring non-magnetized or electrically non-conductive coatings on magnetized or non-magnetized, electrically conductive base materials.

Measurement electrically insulated coatings on non-magnetized, electrically conductive metals.

Measurement of non-magnetized coatings on magnetized base materials.